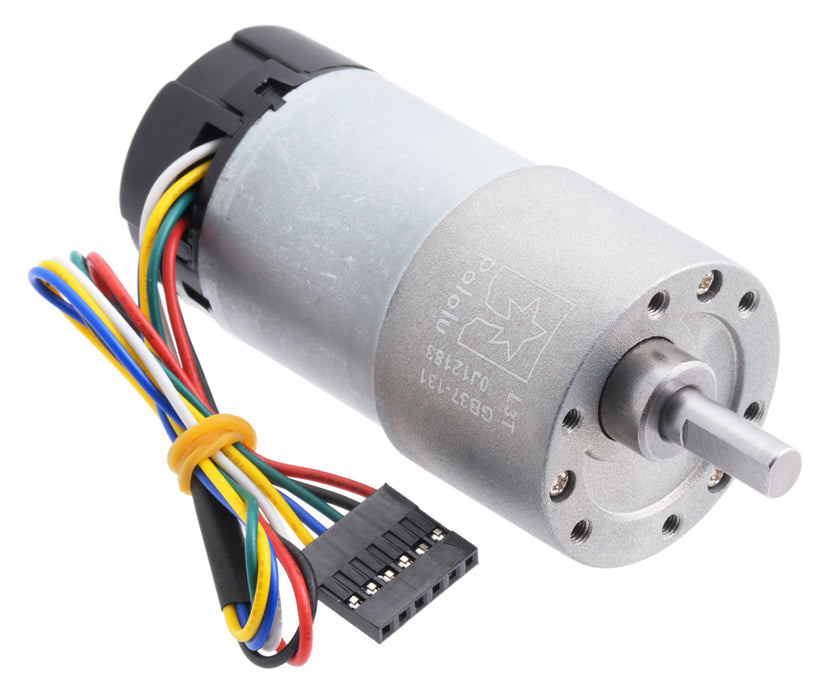

4756 - 131:1 Metal Gearmotor 37Dx73L mm with 64 CPR Encoder (Helical Pinion)

Tutti i prezzi sono IVA inclusa

This gearmotor is a powerful 12V brushed DC motor with a 131.25:1 metal gearbox and an integrated quadrature encoder that provides a resolution of 64 counts per revolution of the motor shaft, which corresponds to 8400 counts per revolution of the gearbox’s output shaft. The gearbox is composed mainly of spur gears, but it features helical gears for the first stage for reduced noise and improved efficiency. These units have a 16 mm-long, 6 mm-diameter D-shaped output shaft.

Key specifications:

| voltage | no-load performance | stall extrapolation |

|---|---|---|

| 12 V | 76 RPM, 150 mA | 45 kg⋅cm (630 oz⋅in), 5.5 A |

Note: Stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. In order to avoid damaging the gearbox, we recommend keeping continuously applied loads under 10 kg-cm (150 oz-in), and the recommended upper limit for instantaneous torque is 25 kg-cm (350 oz-in). Stalls can also result in rapid (potentially on the order of seconds) thermal damage to the motor windings and brushes; a general recommendation for brushed DC motor operation is 25% or less of the stall current.

These motors are intended for use at 12 V, though in general, these kinds of motors can run at voltages above and below the nominal voltage (they can begin rotating at voltages as low as 1 V). Lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor.

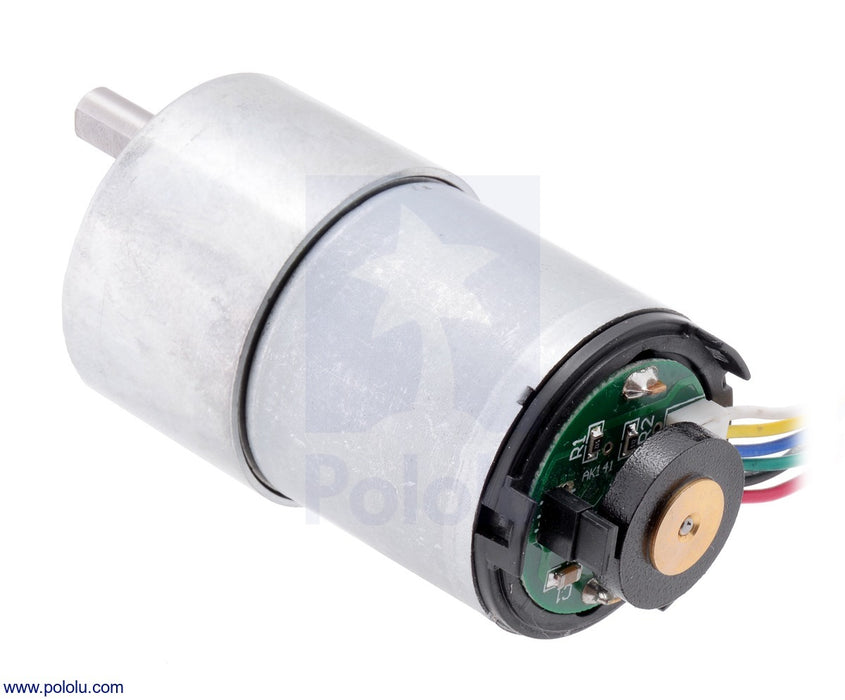

Using the Encoder

A two-channel Hall effect encoder is used to sense the rotation of a magnetic disk on a rear protrusion of the motor shaft. The quadrature encoder provides a resolution of 64 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output, multiply the gear ratio by 64. The motor/encoder has six color-coded, 8″ (20 cm) leads terminated by a 1×6 female header with a 0.1″ pitch, as shown in the main product picture. This header works with standard 0.1″ male headers and our male jumper and precrimped wires. If this header is not convenient for your application, you can pull the crimped wires out of the header or cut the header off.

Dimensions

| Size: | 37D × 72.5L mm1 |

|---|---|

| Weight: | 210 g |

| Shaft diameter: | 6 mm2 |

General specifications

| Gear ratio: | 131.25:1 |

|---|---|

| No-load speed @ 12V: | 76 rpm |

| No-load current @ 12V: | 0.15 A |

| Stall current @ 12V: | 5.5 A3 |

| Stall torque @ 12V: | 45 kg·cm3 |

| Max output power @ 12V: | 6 W |

| No-load speed @ 6V: | 38 rpm4 |

| No-load current @ 6V: | 0.1 A4 |

| Stall current @ 6V: | 3.0 A5 |

| Stall torque @ 6V: | 28 kg·cm5 |

Performance at maximum efficiency

| Max efficiency @ 12V: | 45 % |

|---|---|

| Speed at max efficiency: | 66 rpm |

| Torque at max efficiency: | 6.0 kg·cm |

| Current at max efficiency: | 0.74 A |

| Output power at max efficiency: | 4.1 W |

General specifications

| Lead length: | 20 cm6 |

|---|---|

| Encoders?: | Y |

| Encoder resolution: | 64 CPR |

Notes:

- 1 Length measurement is from gearbox face plate to back of encoder cap (it does not include the output shaft). See dimension diagram for details.

- 2 D shaft.

- 3 Stalling is likely to damage the gearmotor. Stall parameters come from a theoretical extrapolation of performance at loads far from stall. As the motor heats up, as happens as it approaches an actual stall, the stall torque and current decrease.

- 4 This motor will run at 6 V but is intended for operation at 12 V.

- 5 Stalling is likely to damage the gearmotor. Stall parameters come from a theoretical extrapolation of performance at loads far from stall. This motor will run at 6 V but is intended for operation at 12 V.

- 6 May vary by a few centimeters.